#1 Wood Floor Company in Boca Raton, FL

Call us today at: 561-843-3694

Wood Floor Installation, Sanding, Refinishing, Staircases, Sub-Floor, Doors, Trim.

Types of Floors – Kingdom Floors of Boca Raton, Inc.

Solid Hardwood flooring

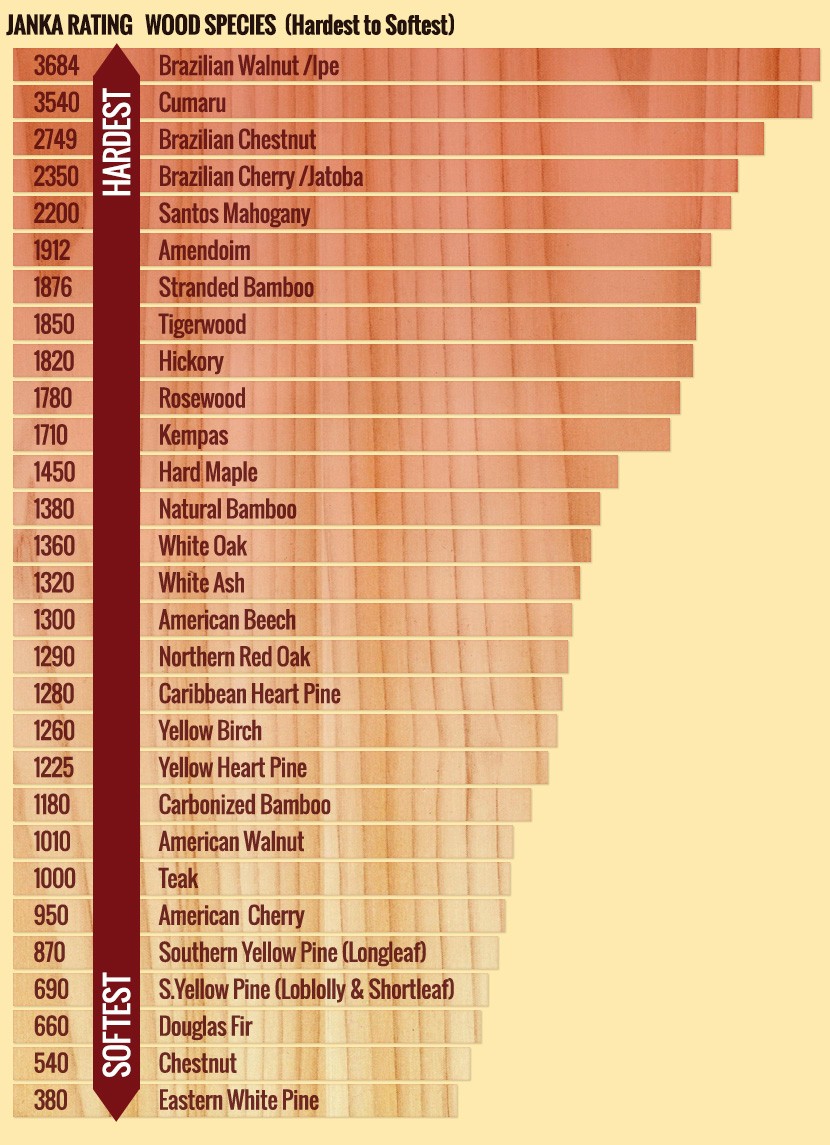

Solid hardwood floors are made of planks milled from a single piece of timber. Solid hardwood floors were originally used for structural purposes, being installed perpendicular to the wooden support beams of a building known as joists or bearers. With the increased use of concrete as a subfloor in some parts of the world, engineered wood flooring has gained some popularity. However, solid wood floors are still common and popular. Solid wood floors have a thicker wear surface and can be sanded and finished more times than an engineered wood floor.

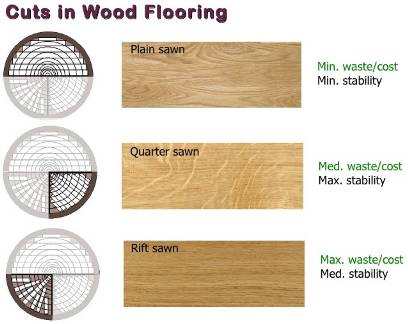

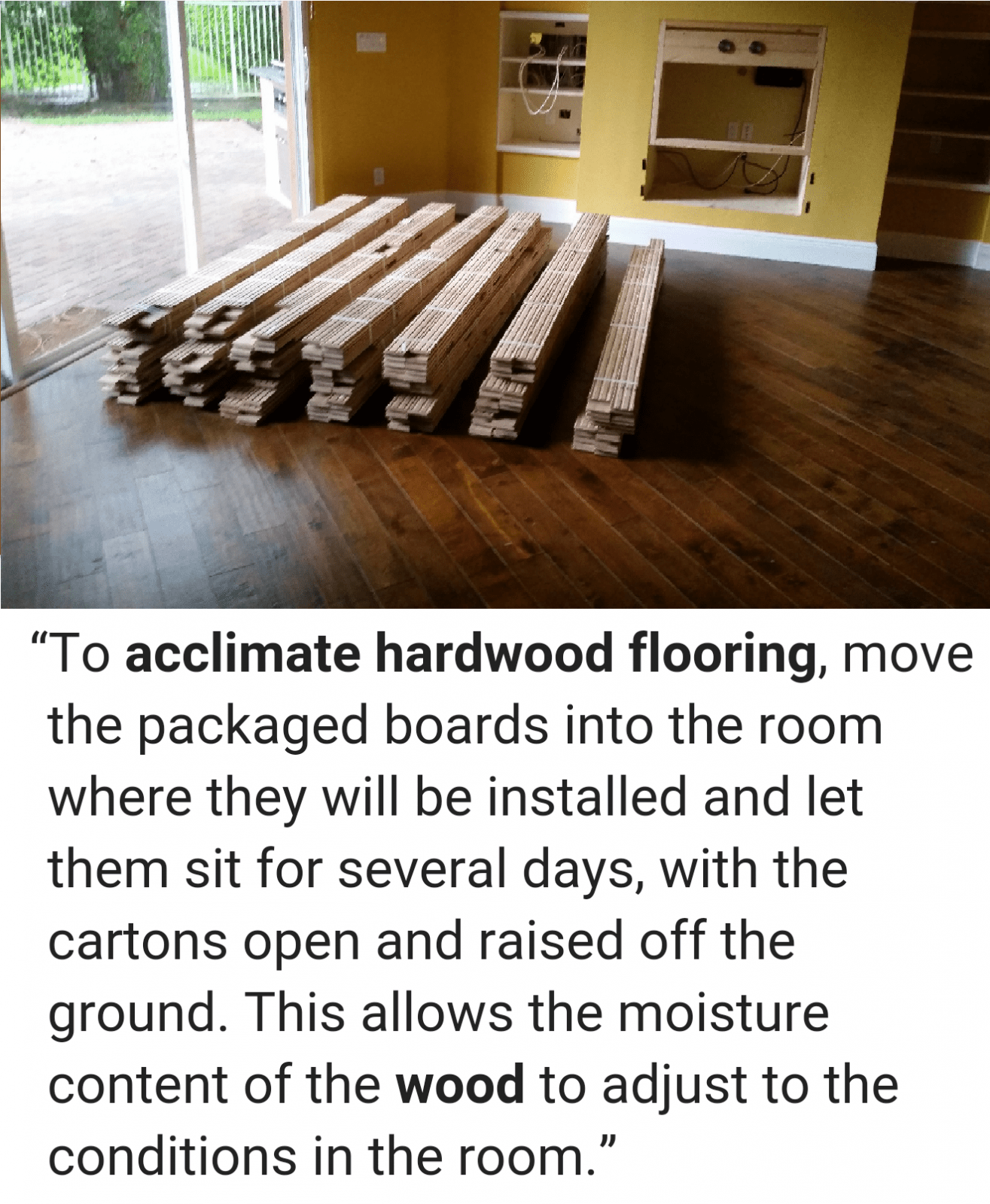

Solid wood flooring is milled from a single piece of timber that is kiln or air dried before sawing. Depending on the desired look of the floor, the timber can be cut in three ways: flat-sawn, quarter-sawn, and rift-sawn. The timber is cut to the desired dimensions and either packed unfinished for a site-finished installation or finished at the factory. The moisture content at time of manufacturing is carefully controlled to ensure the product doesn’t warp during transport and storage.

There are a number of proprietary features for solid wood floors that are available. Many solid woods come with grooves cut into the back of the wood that run the length of each plank, often called ‘absorption strips,’ that are intended to reduce cupping. Solid wood floors are mostly manufactured .75 inches (19 mm) thick with a tongue-and-groove for installation.

Engineered Wood

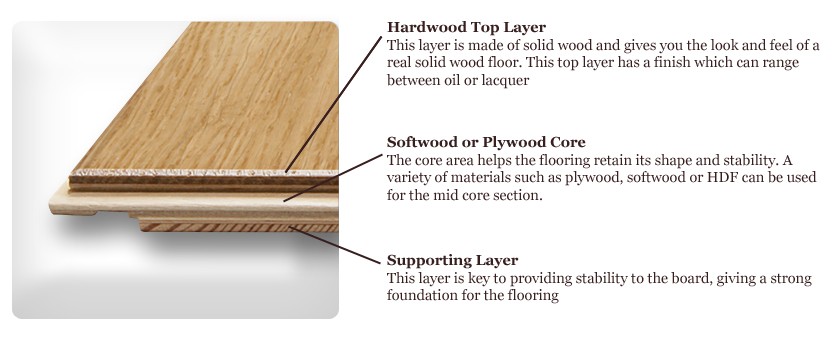

Engineered wood flooring is composed of two or more layers of wood in the form of a plank. The top layer (lamella) is the wood that is visible when the flooring is installed and is adhered to the core.

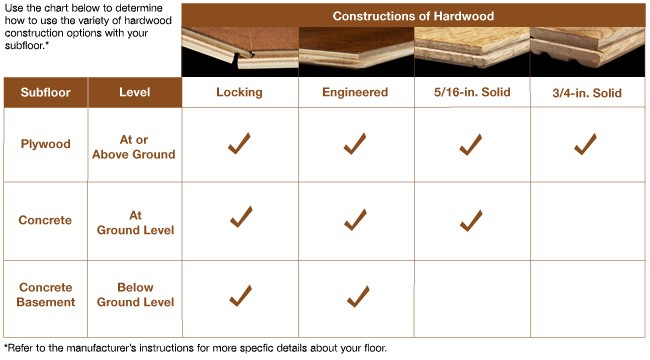

The increased stability of engineered wood is achieved by running each layer at a 90 degree angle to the layer above. This stability makes it a universal product that can be installed over all types of subfloors above, below or on grade.

Laminate Flooring

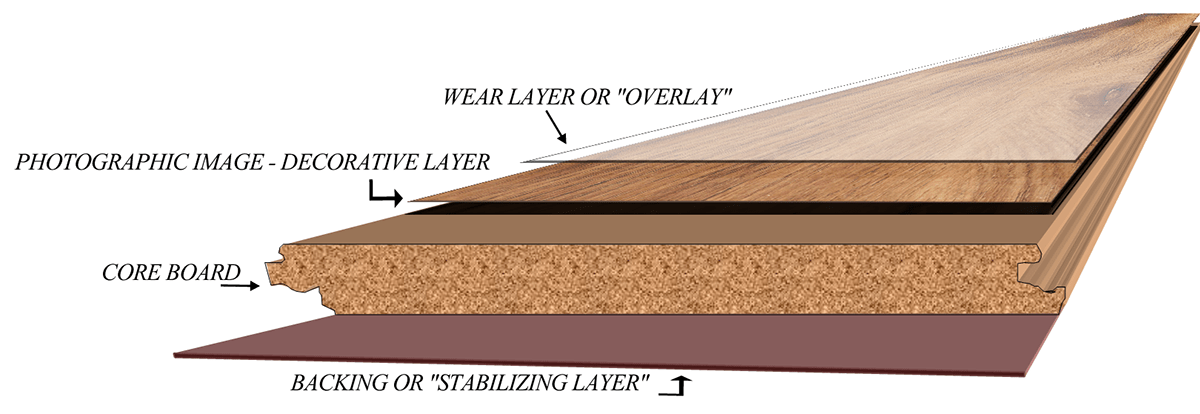

Is a multi-layer synthetic flooring product fused together with a lamination process. Laminate flooring simulates wood with a photographic layer under a clear protective layer. The inner core layer is usually composed of melamine resin and fiber board materials.

Laminate flooring has grown significantly in popularity, perhaps because it may be easier to install and maintain than more traditional surfaces such as hardwood flooring It may also have the advantages of costing less and requiring less skill to install than alternative flooring materials. It is reasonably durable.

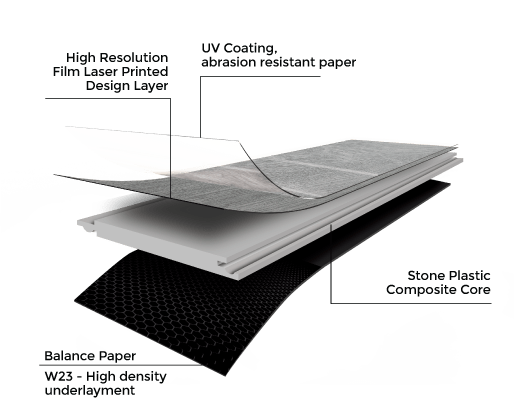

Waterproof SPC Laminate Flooring

SPC Laminate flooring is ideal for every room in the house including kitchens, basement and even full bathrooms, because it is 100% waterproof.

Made of Stone Plastic Composite. The main components are natural limestone powder polyvinyl chloride and stabilizer which combined a very stable composite material. Durable rubber underlayment.

Wood can be manufactured with a variety of different installation systems:

Tongue and groove : One side and one end of the plank have a groove, the other side and end have a tongue (protruding wood along an edge’s center). The tongue and groove fit snugly together, thus joining or aligning the planks, and are not visible once joined. Tongue-and-groove flooring can be installed by glue-down, floating, or nail-down.

Click System : There are a number of patented “click” systems that now exist. These click systems are either “unilin” or “fiboloc” A “click” floor is similar to tongue-and-groove, but instead of fitting directly into the groove, the board must be angled or “tapped” in to make the curved or barbed tongue fit into the modified groove. No adhesive is used when installing a floor, making board replacement easier.

Floor connection system: There are a wide range of connection systems, as most of them are mill-specific manufacturing techniques. The general principle is to have grooves on all four sides of the plank with a separate, unconnected, piece that is inserted into the grooves of two planks to join them. The piece used for the connection can be made from wood, rubber, or plastic. This installation system allows for different materials to be installed together if they have the same connection system.

Wood flooring can also be installed utilizing the glue-down method. This is an especially popular method for solid parquet flooring installations on concrete sub-floors. Additionally, engineered wood flooring may use the glue-down method as well. A layer of mastic is placed onto the sub-floor using a trowel similar to those used in laying ceramic tile. The wood pieces are then laid on top of the glue and hammered into place using a rubber mallet and a protected 2×4 to create a level floor. Often the parquet floor will require sanding and re-finishing after the glue-down installation method due to the small size pieces.

LET KINGDOM FLOORS DO YOUR FLOORS !